Take advantage of our Ammonia Refrigeration Operations program - one of four in the US!

As an operations leader, you know how critical qualified ammonia refrigeration operators are to facility safety, efficiency, and uptime. That’s why NWTI has launched a No-Cost Ammonia Refrigeration Training Program — built for Arkansas industry, with input from Arkansas industry. This new program includes: Introduction to Ammonia Refrigeration Operation and Ammonia Refrigeration Operator I & II.

Our Ammonia Refrigeration Operation programs provide hands-on, real-world instruction to help businesses improve safety, enhance efficiency, and maintain compliance with industry regulations. Whether you need to upskill your current workforce or train new employees, NWTI delivers flexible training solutions tailored to your company’s unique needs.

Partner with NWTI to equip your team with the skills and certifications necessary to thrive in today’s fast-paced industrial environment.

Our Courses

Introduction To Ammonia Refrigeration Operation:

This two-day class provides a comprehensive introduction to ammonia refrigeration systems, focusing on the fundamentals of refrigeration cycles, safety protocols, and key system components. Topics covered include safety standards, such as OSHA PSM and EPA RMP, and the operational principles of evaporators, compressors, condensers, and expansion devices. Participants will also learn about the unique characteristics of ammonia as a refrigerant and explore its applications in large-scale industrial systems. This course is ideal for new operators or individuals looking to gain a foundational understanding of ammonia refrigeration systems.

It emphasizes both theoretical knowledge and practical understanding, preparing students for safe and efficient operation of ammonia-based refrigeration systems.

Ammonia Refrigeration Operator I:

This four-day class provides a foundational understanding of ammonia refrigeration systems, focusing on key components, system operations, and safety protocols. Participants will learn about the refrigeration cycle, including compressors, evaporators, condensers, and vessels. The course emphasizes safe work practices, ammonia characteristics, and compliance with safety standards such as OSHA PSM and EPA RMP. Ideal for new operators, this training equips participants with the necessary knowledge to operate and monitor ammonia refrigeration systems safely and efficiently in an industrial setting.

It covers basic system troubleshooting, operational safety, and essential regulations.

Ammonia Refrigeration Operator II:

This four-day class provides an in-depth review of industrial refrigeration systems, focusing on essential concepts such as heat flow, enthalpy, and the psychrometric chart, as well as the operational characteristics of various refrigeration systems. Participants will explore system components, including low-side liquid feed valves, direct expansion, and liquid overfeed systems. The course also covers safety practices, defrost processes, and two-stage systems used in low-temperature applications. Through comprehensive instruction and real-world examples, students will gain the skills needed to operate and maintain industrial refrigeration systems effectively and safely.

This course is ideal for refrigeration engineers and technicians looking to deepen their technical knowledge and operational efficiency in industrial refrigeration environments.

Where you'll train:

NWTI Industrial Maintenance & Ammonia Refrigeration Technology (IMART) Building

Springdale, AR

Where to fly:

Northwest Arkansas National Airport (XNA)

Bentonville, AR

Where to stay:

Holiday Inn Springdale/Fayetteville Area

1500 South 48th Street, Springdale, AR

(479)601-8450

BOOK NOW

Home2 Suites by Hilton Springdale

1519 S. 48th St. Springdale, AR 72762

BOOK NOW

Hampton Inn & Suites Springdale

1700 S. 48th Street Springdale, AR 72762

BOOK NOW

Hyatt Place Fayetteville/Springdale

348 East Van Asche, Fayetteville, AR 72703

(479)756-6101

BOOK NOW

Fairfield Inn & Suites Fayetteville

755 Van Asche Dr, Fayetteville, AR 72703

479-551-9270

BOOK NOW

When you'll train:

Introduction to Ammonia Refrigeration Operation (Choose One)

April 31 & May 1, 2025

May 5 & 6, 2025

June 2 & 3, 2025

Ammonia Refrigeration Operator I (Choose One)

May 12-15, 2025

June 9-12, 2025

Employees can finish crucial IMART training in a week with flexible, modular courses designed to accommodate individual skill levels and paces. Training options are stackable, ensuring a seamless path for continuous skill development.

How to register:

Fill out an Offer Form or contact Jeremy Sherman.

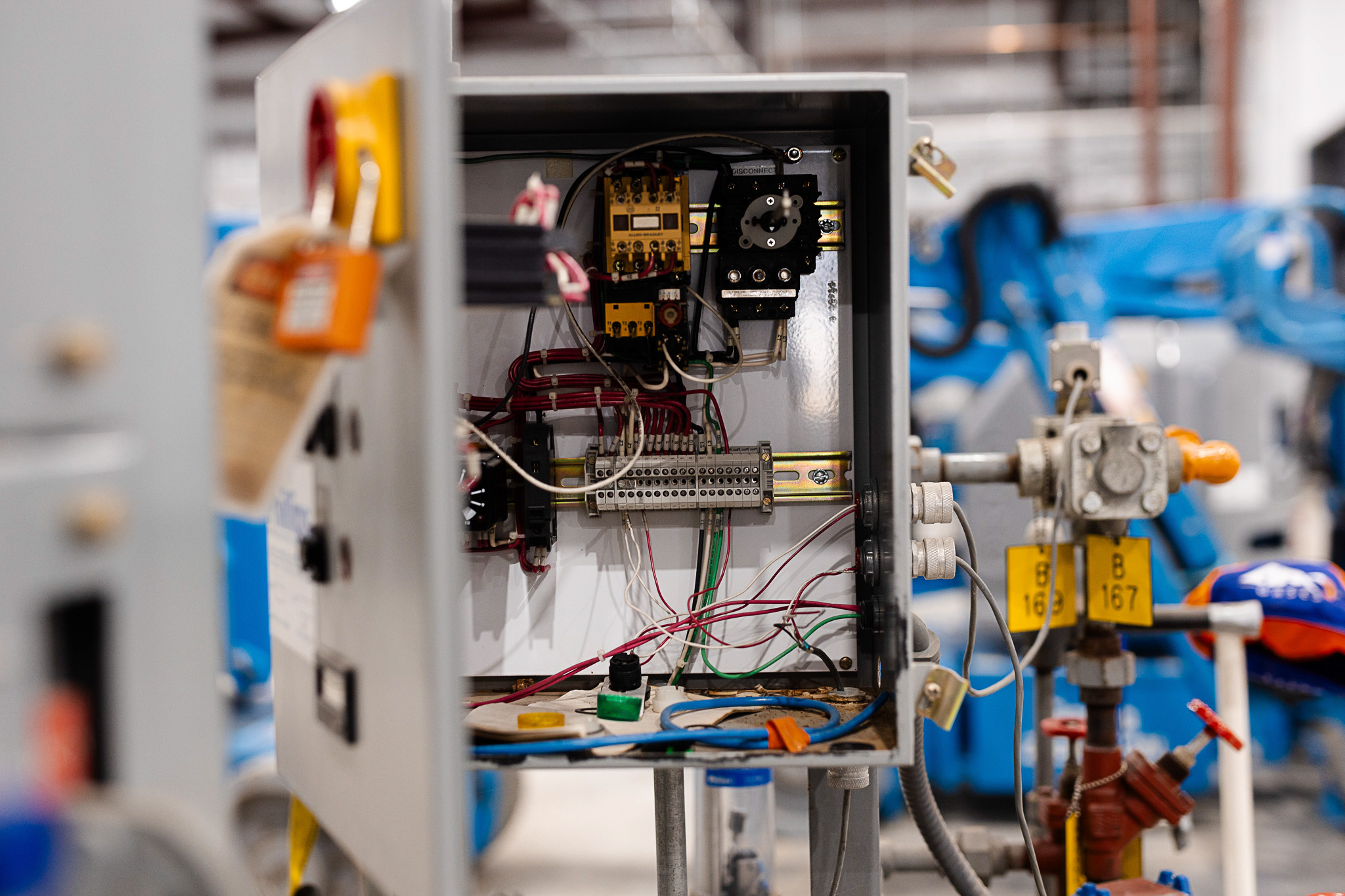

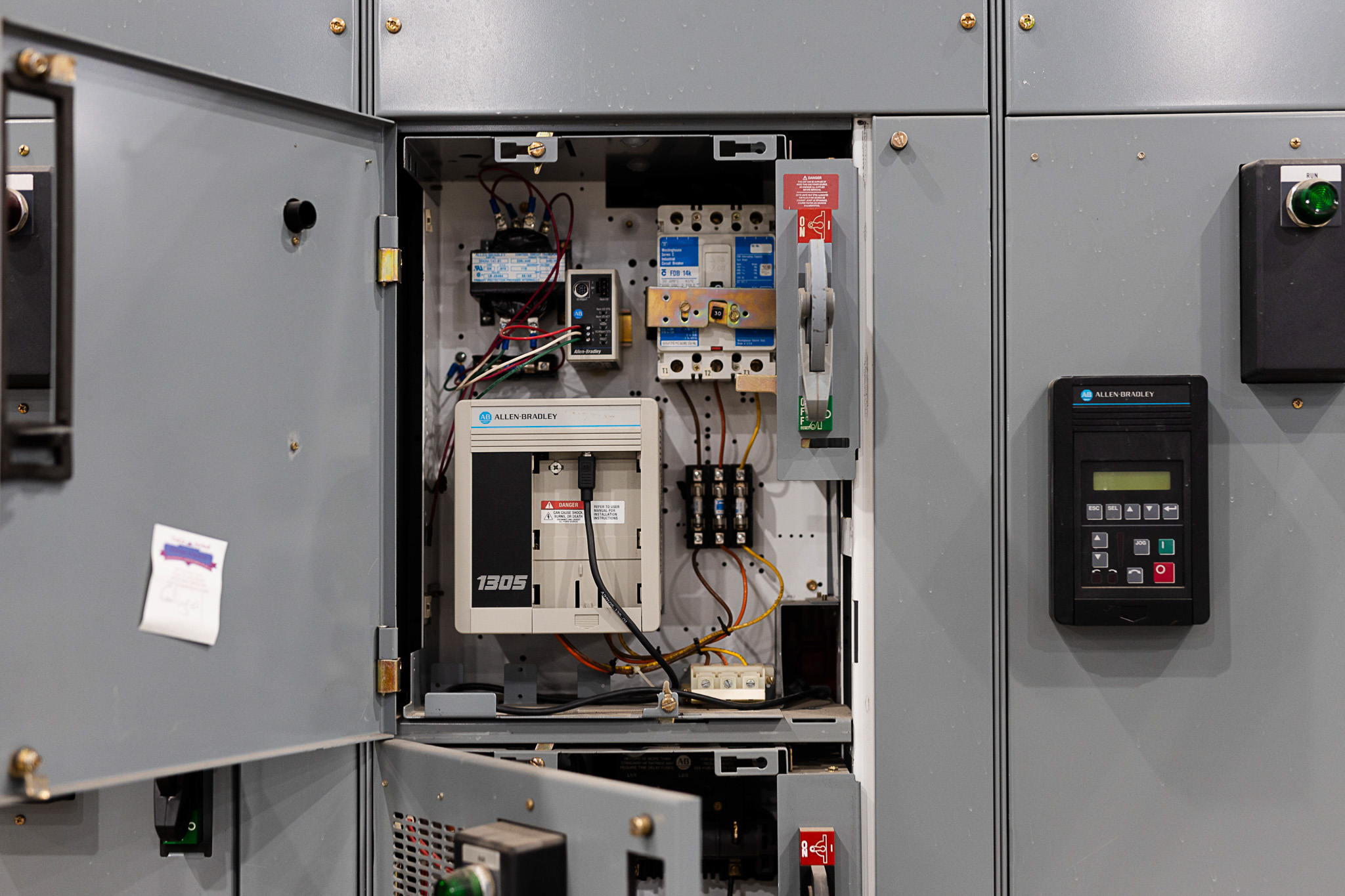

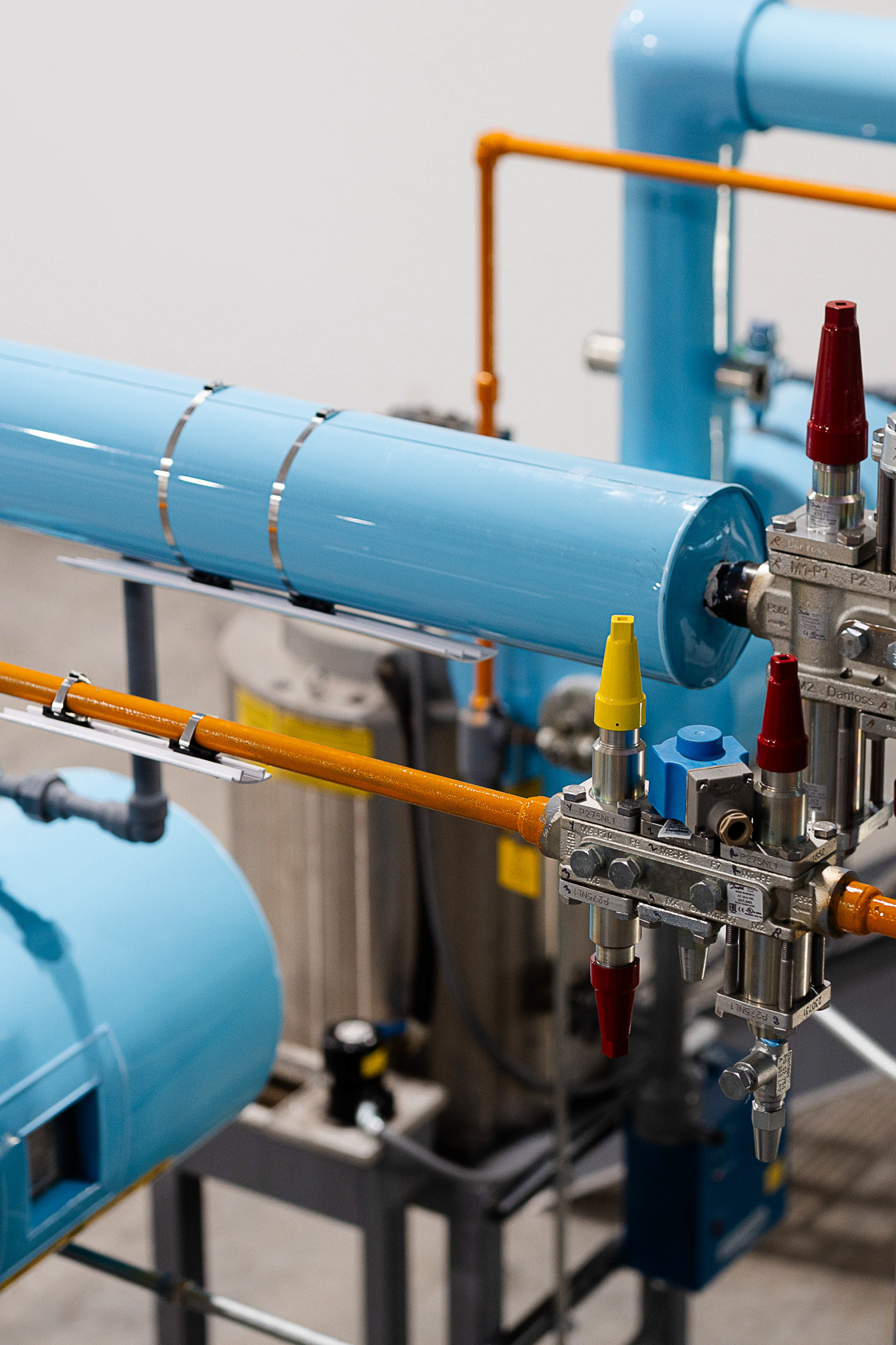

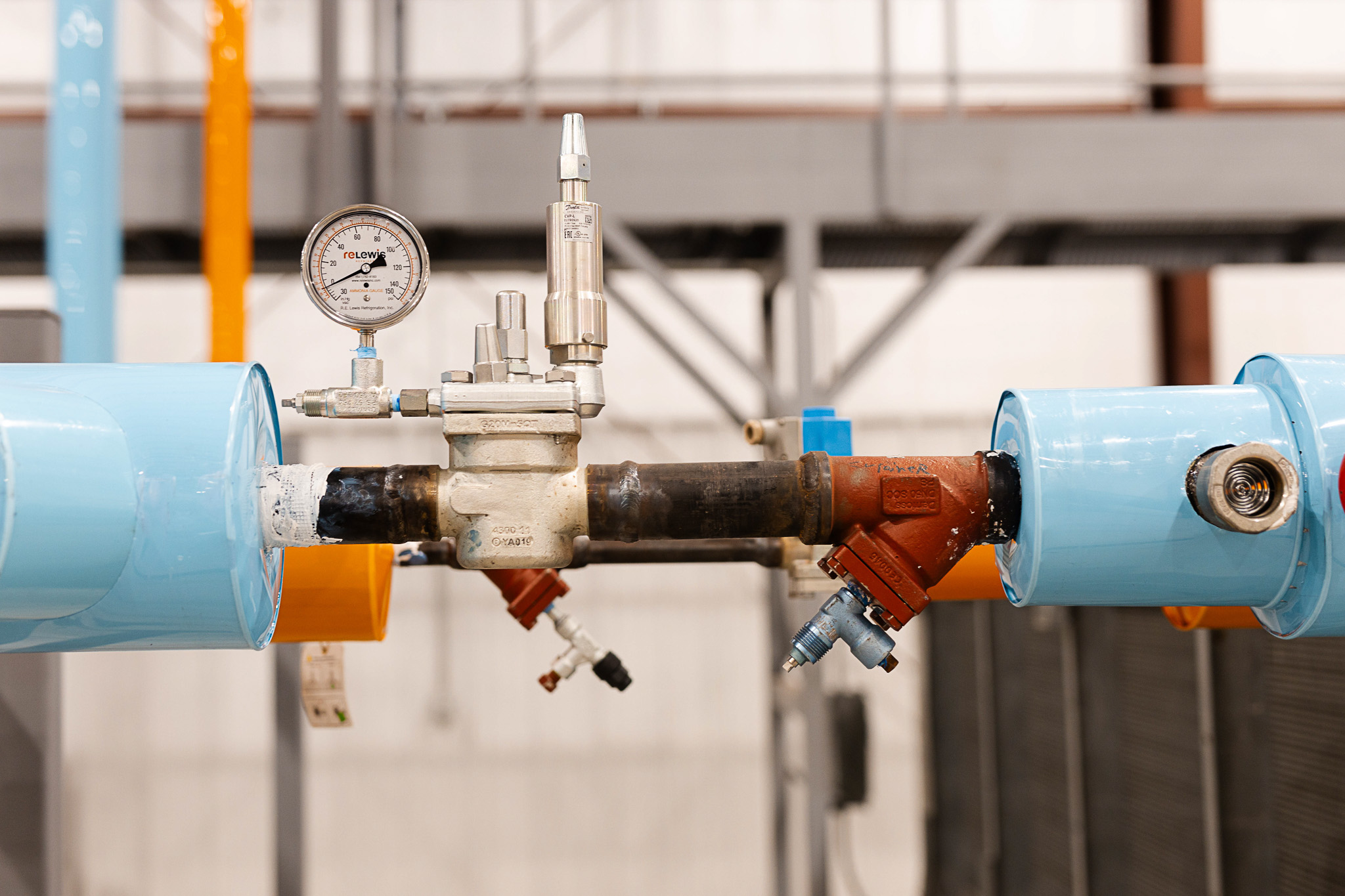

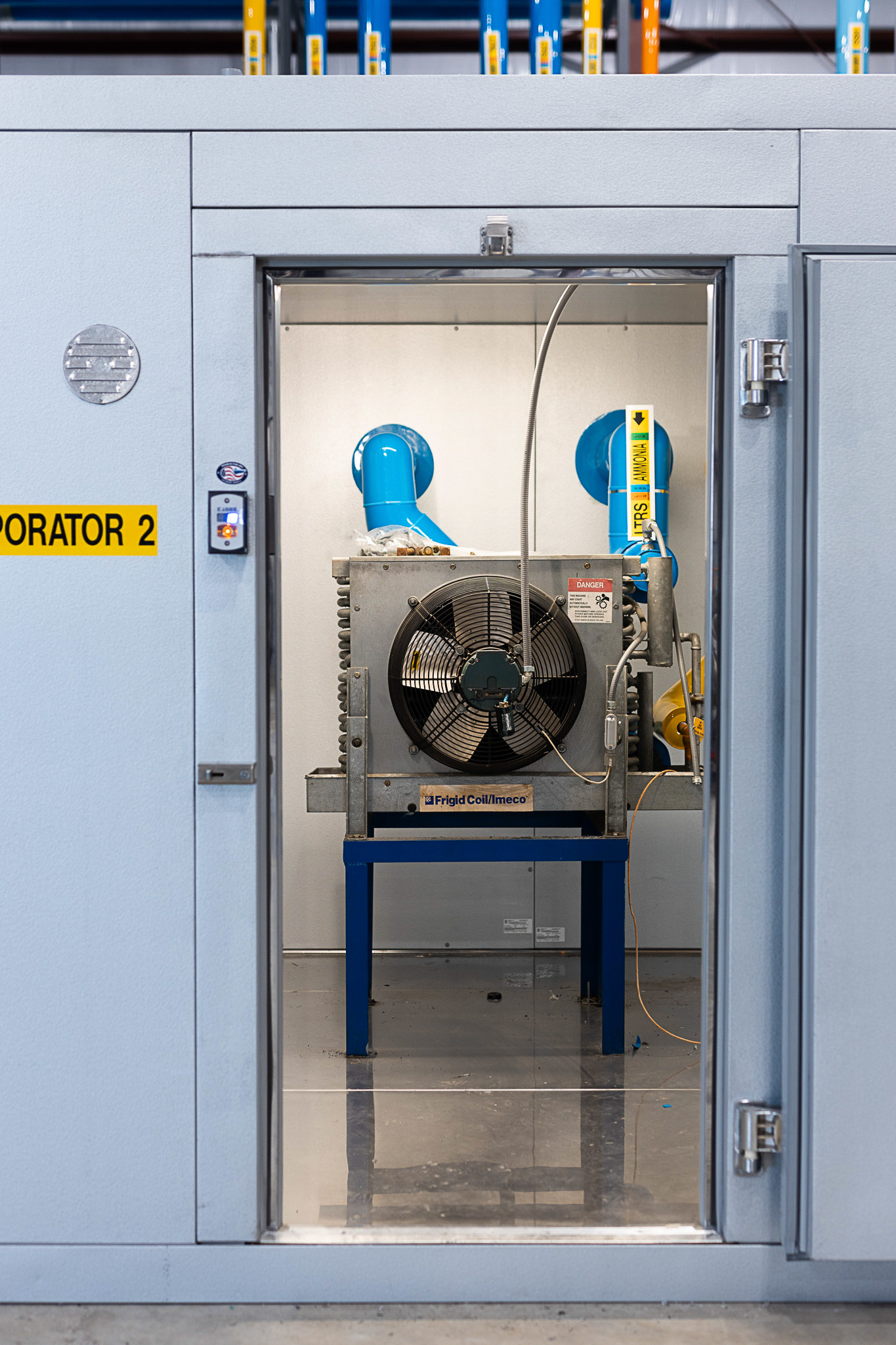

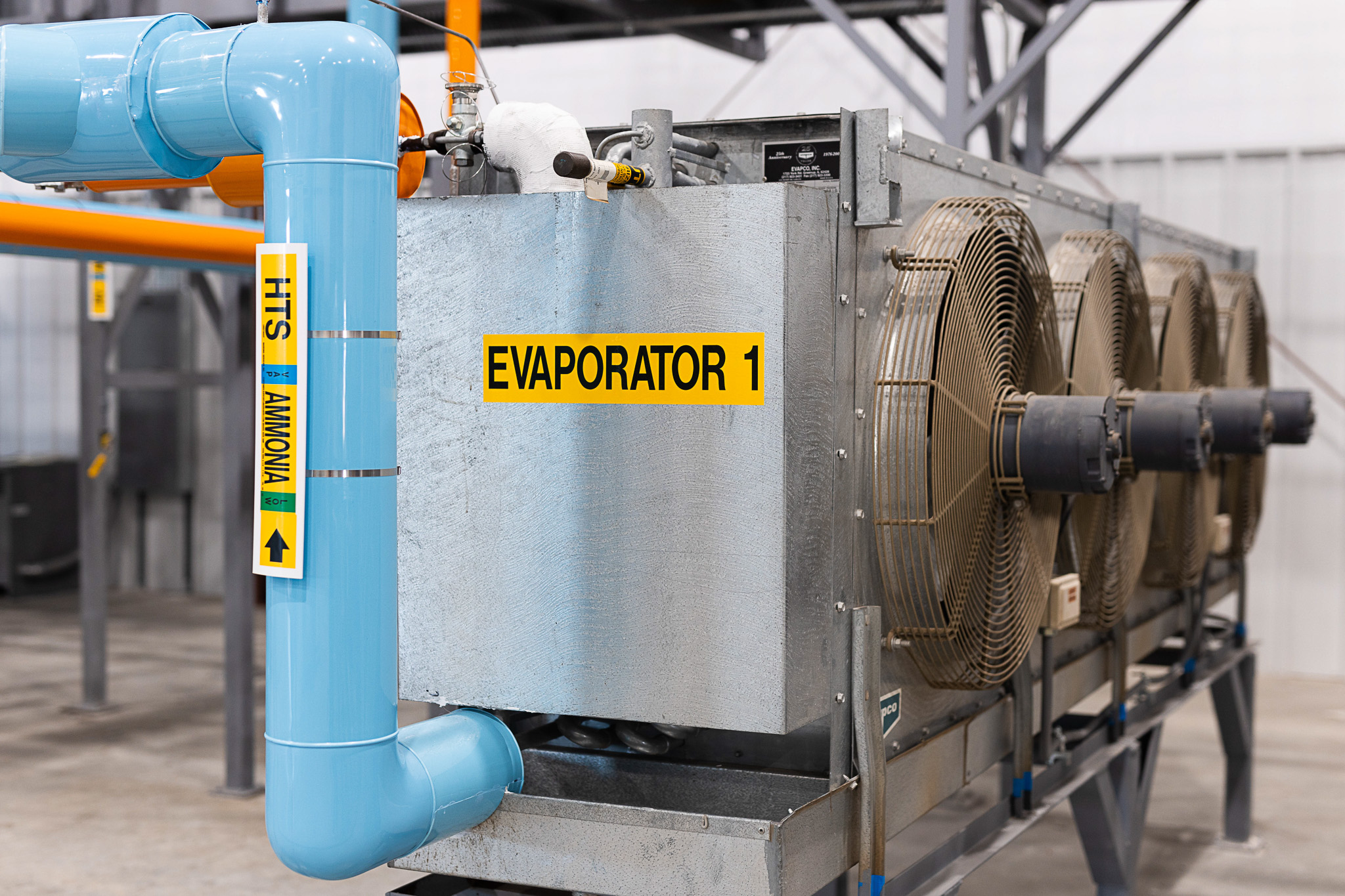

Our Equipment

Students train on various industry-grade equipment, ensuring they gain experience with the same advanced systems used in the field. From refrigeration compressors and control systems to hydraulic, pneumatic, and electrical troubleshooting tools, our training environment mirrors real-world industrial settings, giving participants the confidence and technical skills to excel on the job.

COMING SOON: A virtual tour of our entire Industrial Maintenance facility!

Our Instructors

NWTI instructors are lifelong industry experts with years of hands-on experience in ammonia refrigeration, industrial maintenance, and manufacturing operations. Their deep knowledge and practical insights provide students with real-world applications and problem-solving skills essential for success in today’s fast-paced industrial workforce.

Customized Industry Training:

In addition to Ammonia Refrigeration Operation courses, NWTI offers a wide variety of flexible, high-quality training designed for your workforce. These include, but are not limited to:

Industrial Maintenance - Hands-on instruction in electrical, mechanical, hydraulic, and pneumatic systems.

Welding & Fabrication – Practical training in welding techniques, blueprint reading, and metal fabrication.

HVAC & Electrical Systems – Training on heating, ventilation, air conditioning, and electrical troubleshooting.

Commercial Truck Driving (CDL) – Professional driver training to meet regional and national transportation needs.

Electronics & Automation – Robotics, automation, and process control for modern manufacturing environments.

Workplace Safety & Compliance – OSHA, HAZMAT, and other essential safety certifications.

Let NWTI help you build a stronger workforce. Contact us today to develop a training program customized to your needs.